Many pieces of plant and equipment have motors and other electromechanical devices. These devices are found in refrigerators, freezers, compressors, heat pumps (both ASHP and GSHP systems) and numerous other products. Like everything ever man-made, products eventually ware out; and it’s usually the mechanical part of the electromechanical device that starts to fail. This causes the equipment to draw more current leading to overheating or even fire. A HeatingSave equipment temperature and condition monitoring system is the ideal way to provide an “early warning” of the above situation.

It does this by constantly measuring the temperature of the equipment using stainless steel probe sensors and using this data to spot unusual rises in temperature. It also measures the ambient temperature of the environment within close proximity to the equipment as well as other airborne parameters such as volatile organic compounds, relative humidity and sound. Together, these can indicate that all is not well?

Plastics in particular change these parameters if they are subjected to continuous and increasing low-level heat.

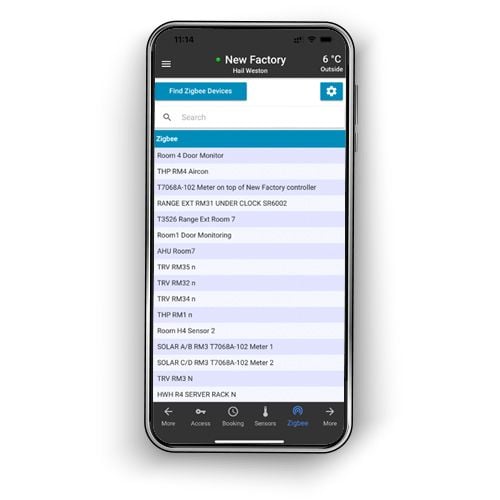

Sensor data is wirelessly transmitted to the HeatingSave T3521 hub which is connected to an Internet router. The user is then able to access the software within the T3521, via any web browser on a PC, laptop or mobile device, to set parameters and create email and Text alerts if things go wrong.

Another great feature of the HeatingSave equipment temperature and condition monitoring system is the smart phone app that “talks” to you warning of critical conditions that require you can take immediate action. The beauty of this system is that you do not have to be at the property where the problem occurs. Speech alerts also are particularly useful for night-time wakeup calls or for those who are visually impaired.

The essential features of the HeatingSave equipment temperature and condition monitoring system

- Probe temperature sensor for equipment monitoring

- Ambient air temperature

- Airborne volatile organic compound and air quality detection

- Sound monitoring of the plant

- Smart Phone audible speech alerts, helpful if at night or you are visually impaired

- Data audit trail of exactly what has happened and what went wrong – due diligence

- Any number of pieces of equipment can be monitored at a particular site/address

- Any number of sites/addresses can be monitored within one HeatingSave system

T3521 web based software

The T3521 hub has powerful graphics and visualisation analysis software that allows alerted users to review the condition of monitored equipment, plant and machinery. This is the 2nd line support facility so that a detailed analysis of the situation can be performed before people have to physically visit the site where the fault seems to have occured?